Testing that Reaches the World

Electromagnetic Compatibility (EMC)

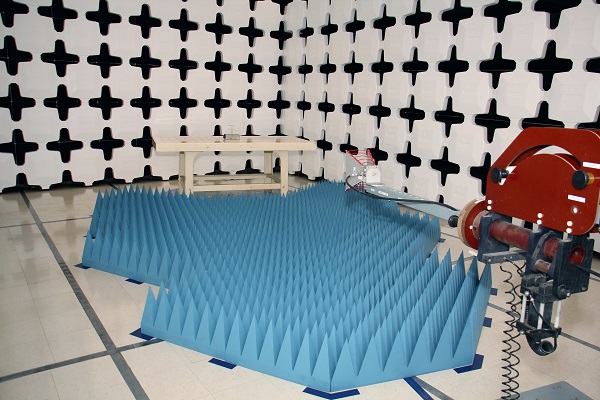

Clark Testing has a fully accredited EMC laboratory providing compliance testing for equipment manufacturers throughout the United States. Clark Testing's EMC lab is 17025 accredited by A2LA. We provide manufacturers product certification and validation services as well as pre-compliance and compliance qualification for a wide range of industries. Our EMC compliance testing services are uniquely complimented by our vibration, seismic, shock and thermal aging capabilities. Clark is the lab of choice with a broad array of environmental testing capabilities enabling our clients to benefit from a single source for all their testing needs.

Clark Testing has several state of the art EMC/EMI chambers which are equipped to handle many industry requirements such as Military, Power Generation, Aerospace, Automotive, Telecom, and Medical.  Whether your project is in the design, development, or pre-compliance and qualification stages, our experienced staff will provide you with top quality and timely results.

Whether your project is in the design, development, or pre-compliance and qualification stages, our experienced staff will provide you with top quality and timely results.

We are adding new capabilities to the Clark Testing laboratory monthly, targeting additional compliance standards to meet our customers' need for to introduce new products to market quickly and with confidence.

Rail Industry

The Railway electromagnetic environment is intricate. Multiple systems coexist and operate simultaneously to achieve safe and efficient transportation of goods and people. These systems like signaling or telecommunications are required to operate in an often harsh conditions created by the electrified railway and propulsion systems used. These systems and the increasing spectral crowding create electromagnetic interference (EMI) that needs to be dealt with to insure the safety and continued operation of today’s Trains.

Some common standards used for railway electromagnetic compatibility (EMC) are:

- IEC 62236: Railway Applications- Electromagnetic Compatibility

- EN 50121: Railway Applications- Electromagnetic Compatibility

- EN 55011: Industrial, scientific and medical (ISM) radio-frequency equipment – Electromagnetic disturbance characteristics – Limits and methods of measurement

- EN 55022: Information Technology Equipment – Radio disturbance characteristics – Limits and methods of measurement

- EN 50121-3-2: Rolling stock – Apparatus

- EN 50121-3-1: Rolling stock Train and complete vehicle

- EN 50121-4: Emission and immunity of the signaling and telecommunications apparatus

Nuclear Power and Power Generation

For over 25 years Clark Testing has supported the Nuclear Power industry providing testing and project management for all aspects of Nuclear EQ (equipment qualification) programs, from EMC to Seismic. With the integration of digital instrumentation and control (I&C) systems replacing the obsolete analog systems, the Nuclear Regulatory Commission (NRC) uses the test methods and levels from the Electric Power and Research Institute (EPRI) called out in the EPRI TR-102323. EPRI initially surveyed seven nuclear power plants in the United States to craft the emission limits and immunity levels. Since the initial release of EPRI TR-102323 in 1994 the NRC has created its own document, the NRC Regulatory Guide RG 1.180, released in 2000 and references the EPRI TR-102323. The guidance and test programs laid out in these documents is intended to control emissions from the next generation digital I&C equipment and electronic systems to minimize electromagnetic interference and establish immunity performance so the equipment can stand up in the Plant’s electromagnetic environment.

Some common standards used for Nuclear electromagnetic compatibility (EMC) are:

- Nuclear Regulation Guide 1.180- GUIDELINES FOR EVALUATING ELECTROMAGNETIC AND RADIO-FREQUENCY INTERFERENCE IN SAFETY-RELATED INSTRUMENTATION AND CONTROL SYSTEMS

- EPRI 102323-1- GUIDELINES FOR EVALUATING ELECTROMAGNETIC AND RADIO-FREQUENCY INTERFERENCE IN SAFETY-RELATED INSTRUMENTATION AND CONTROL SYSTEMS

- MIL-STD 461- MILITARY STANDARD: ELECTROMAGNETIC INTERFERENCE CHARACTERISTICS REQUIREMENTS FOR EQUIPMENT

Military Testing

Military equipment and devices need to be able to withstand the most demanding requirements. From changing environments to active threats, commercial designs can be terribly inadequate for military applications. Because of the unique applications most military equipment will be subject to, Military EMC requirements were developed. MIL-STD 461 covers multiple platforms and installations with different limits and levels for each. Table IV below shows the available tests in 461 while table V show applicability for each application.

EMC Standards Break Down

IEC Standards

EN Standards

- EN 55011 (Emissions)

- EN 61000-6-4 (Emissions)

- EN 61000-4-2 (Immunity)

- EN 61000-4-3 (Immunity)

- EN 61000-4-4 (Immunity)

- EN 61000-4-5 (Immunity)

- EN 61000-4-6 (Immunity)

- EN 61000-4-8 (Immunity)

- EN 61000-4-9 (Immunity)

- EN 61000-4-10 (Immunity)

- EN 61000-4-11 (Immunity)

- EN 61000-4-12 (Immunity)

- EN 61000-4-13 (Immunity)

- EN 61000-4-29 (Immunity)

FCC Standards:

- ANSI C63.4

Military Standards:

- MIL-STD 461 E,F,G