Testing that Reaches the World

Benchmark Testing

With today's rapid pace of business decisions and cycles, companies constantly face the of danger losing market share due to competitor's new product development or market disrupters that can potentially change an industry. In this competitive environment, it is critical for companies to have impartial data on how their products measure up to the competition. Manufacturing companies often rely on benchmark testing to make critical decisions on product lines, product development initiatives and marketing campaigns. Benchmark testing is a data driven resource for management to measure their product's competitive position and make strategic business decisions. Clark Testing's Benchmark Testing Services (BTS) provides customers with the data and analysis to measure their products based on appropriate metrics. Manufacturers use this information to gain a perspective on a range of competitive factors from pricing to product reliability within their respective industries. Benchmarking is an investment in success, offering manufacturers critical information for making strategic decisions.

Why conduct benchmark testing:

- Compare company products to competitors for quality and reliability.

- Provide product analysis with competitor price comparison.

- Determine which products best meet the market demands.

- Promote new product development initiatives.

- Launch targeted marketing campaign showing competitive advantage.

- Allow company to consider internal value proposition of certain product lines.

Manufactures and producers often want competitor data in order to understand how their products measure up within the market. This stimulates product development decisions and supports marketing initiatives based on competitive advantages with proven, impartial data.

There are several critical aspects to consider when conducting a product-benchmarking study program. The legitimacy and unbiased nature of the study will ensure the data is defensible and the market accepts the results.

Critical aspects of benchmarking include:

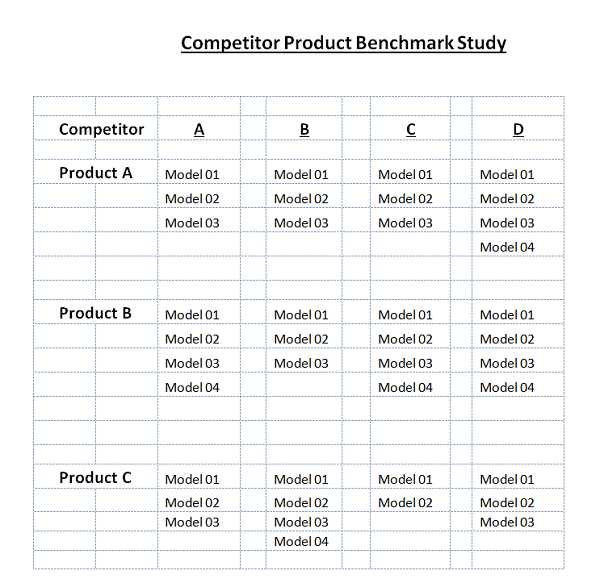

- Matching the competitor products to the appropriate company product models. This ensure the family of the competitors’ products are measured against the correct specification.

- It is recommended to buy several models of products or components when doing a benchmark survey. (The product acquisition chart below shows an example of a typical competitor product selection.)

- Be sure that the models are representative of your base models in terms of specifications, capacities and capabilities.

- If there are variances, a technical justification may be able to validate the comparison.

- Companies can sometimes justify a comparison by computer modeling products.

- Gather the entire population of competitor inventory. It is critical when doing a benchmark test that the company conducting the study includes all competitors therefore not cherry picking certain competitor products.

It is critical to keep develop a detailed data file that includes a chain of documentation that will be used to defend the impartial basis of the study.

Documentation must include:

- Purchase orders of all transactions including dates, model numbers & lot numbers when applicable. Detailed data sheets provided by companies will be critical to back up the final report of the study.

- The test lab should match the company data sheets, shipping manifests, purchase orders, lot numbers and other assorted details of the products purchased.

- Results of benchmark testing in the form of a report on all products including lead company conducting the study.

The test laboratory should be a certified according to an ISO accredited standard. This will support or further qualify the study with an accredited lab that has audited by a recognized authority.

The accredited laboratory should ensure the following steps for the benchmarking program:

- Test equipment and data systems must be calibrated to a traceable standard.

- All data files including failures are critical to validate the credibility of the test program.

- Test lab should be an accredited laboratory that will be able to provide audits of their procedures.

- Test reports and data logs must include all activities of the benchmarking and test programs.

- rush, and cyclical aging on batteries and UPS systems.Any data sheets and company description and specifications of the competitor’s products. Standard test procedures should be developed before the benchmark testing begins.Testing must be consistent with all products in the study.