Testing that Reaches the World

High Impact Medium Weight Shock Testing

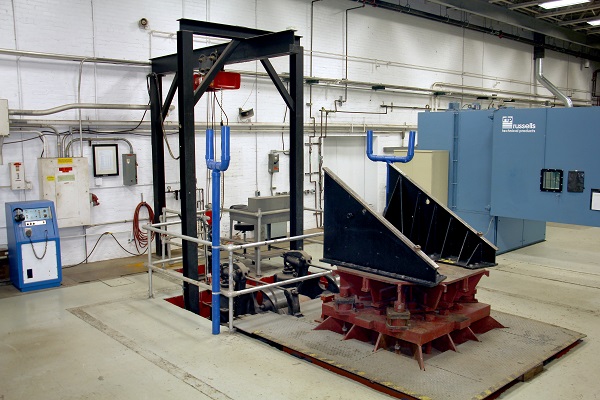

Clark Dynamics MIL-Std-901D shock stand simulates the high impact medium weight shock requirement for shipboard equipment in accordance with NAVSEA. Shock loading for shipboard equipment is categorized in accordance with several standards including grades, classes, and types of equipment. Each category defines the unit's importance to the ship operations, method of installation within the ship structure, and required performance during shock testing.

Clark’s MIL-Std-901D medium weight shock stand has been NAVSEA approved and can test equipment with multiple mounting configurations. The test stand is a pendulum/hammer system with a 3,000# hammer that strikes the base of the test frame. The maximum weight capacity of a test article for the MIL 901D medium weight shock test is 7,000 lb.

Shipboard equipment can be tested in accordance with three categories. Lightweight, medium weight and Heavyweight test specifications. The tests are classified into two shock grades, A & B.

Shipboard equipment can be tested in accordance with three categories. Lightweight, medium weight and Heavyweight test specifications. The tests are classified into two shock grades, A & B.

- Grade A

- are items that are essential to the safety and capability of the combat ship to operate.

- Grade B

- are items whose operation is non-essential for the ship to operate in combat but could become a hazard the ship personnel operating grade equipment or could be upgraded to grade A as a result of exposure to shock.

Along with the categories of test and grades of equipment, MIL-S-901 classifies equipment in based on mounting requirements of the equipment. These requirements define the mounting of the shipboard equipment being able to meet the shock, noise or vibration requirements with or without the use isolation equipment. The equipment classifications are as follows:

- Class Ⅰ

- Equipment required to meet shock specifications without the use of resilient or isolation mountings.

- Class Ⅱ

- Equipment which meets shock requirements with the use of resilient mountings.

- Class Ⅲ

- Equipment which may be mounted on a ship with or without the use of resilient mountings installed between the item and the ship structure; therefore required to meet both class I and class II requirements.

In addition to the types of shock testing classifications and shipboard equipment mounting requirements, MIL-Std-901 also classifies shock test types with the following Test Types:

- Type A

- Test of a principal unit or main component which is directly supported by the ship structure. These items typically include diesel generator sets, steam generators, air conditioning plants, missile launchers and valves if installed in piping which is supported by the ship’s structure.

- Type B

- Test of a subsidiary or secondary component, which is not a major part of a principal unit but may support a principle unit. These typically include items or components that support principles systems.

- Type C

- Test of a subassembly, which is a part of a principal unit or subsidiary component. Subassemblies, systems and subsidiary components can be different in various equipment specifications.

With its legacy as the former Westinghouse Advanced Energy System’s Division, Clark Dynamics has long history of shipboard equipment qualification programs. The MIL-Std-901D shock stand at Clark was one of the pioneer shock test systems installed in the US. During the early period of US naval nuclear program, Admiral Hyman Rickover was often visiting the South Hills of Western Pennsylvania where many of the Naval technology initiatives were being developed. Clark Testing is proud to carry forward this heritage and keep the US Naval technology the premium worldwide.